The addition of an auxiliary reservoir can provide even lower system frequencies. System natural frequencies as low as 60 cpm (1 Hz) are available. Īirmount® isolators can provide the highest degree of isolation of any type vibration isolator. For the same loading, a system using a style 20-2 Airmount® isolator would have a natural frequency with a range from 95 cpm at 3000 lbs to 103 cpm at 1500 lbs. Given that a lower system natural frequency provides superior isolation and that less variability in natural frequency provides more constant isolation, the benefits of the Airmount® are clear.įor example, in an application designed to use either coil springs or air springs to support loads ranging from 1500 lbs to 3000 lbs, a system using a coil spring 8.5 inches tall with a constant spring rate of 1200 lbs per inch would have a natural frequency ranging from 118.9 cpm at 3000 lbs to 171.6 cpm at 1500 lbs. In fact, a coil spring designed to operate at a given height loses isolation efficiency with even very small decreases in the supported load. Traditional constant spring rate isolators such as coil springs do not have this ability to operate with constant efficiency through a wide range of loads. It also means that a single style of air spring can be used at every mounting point of machinery or systems that are unevenly loaded without sacrificing this efficiency at any of the mounting points. The effect of this variable spring rate is that an Airmount® isolator can perform with constant efficiency through a wide range of loads. The variable spring rate is due to air spring geometry, internal air pressure, and changing effective area. Like Marsh Mellow® springs, Airmount® isolators have a variable spring rate. With an air spring, you have a more compliant support.The low natural frequencies and large travel of the air spring allow it to reduce the need for a large inertia mass. However, this is expensive, and is sometimes impossible without serious structural enhancement. This allows a relatively stiff isolator to do an acceptable job, and a more compliant one to do a good job. Most solid forms of isolation devices have historically been used with large inertia masses whose function is to reduce the amplitude of the vibration to within the ability of the isolator to comply to the motion. As a load shifts, air springs can be inflated or deflated to maintain a constant height, and therefore a level surface. An additional benefit is the ability to maintain a level surface with a compliant isolation system. For the designer this gives a generous tolerance to his calculations. An air spring can support loads varying by hundreds or even thousands of pounds with the same effective isolation. While it may be theoretically possible to have a coil spring as effective as an air spring at a particular load, it is impossible to construct a spring that has as wide a load range, or is as effective throughout the range. This gives the designer greater freedom to control the height of his equipment.Īir springs also have a unique capability unavailable in a solid spring: they are adjustable. Installed heights for air springs are normally less than an equivalent coil spring.

#Firestone airmount guide free#

This would necessitate a coil spring with an impossibly long free height. Air springs can be constructed to have spring rates as low as a coil spring with over 9 inches of static deflection.

While it may be theoretically possible to construct a solid isolator that has as low a spring rate as an air spring, it is often impossible practically.

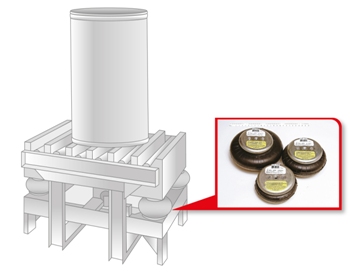

Airmount® Advantages Compact installed height

0 kommentar(er)

0 kommentar(er)